Views: 0 Author: Site Editor Publish Time: 2025-07-05 Origin: Site

Industrial labels face extreme weather conditions, from UV exposure to chemical corrosion. This white paper focuses on six critical label types—polyester, polyimide, vinyl, anodized aluminum, ceramic, and polycarbonate—detailing their weather resistance standards and certifications. The revision emphasizes vinyl labels, a versatile option for harsh environments, while excluding epoxy labels per your request.

Key Takeaway:

Vinyl labels excel in outdoor durability, offering UV resistance, flexibility, and cost-effectiveness, making them ideal for logistics, automotive, and chemical industries.

Understanding Weather Resistance in Industrial Labels

International Standards for Weather-Resistant Labels

Certification Requirements by Label Type (6 Types)

Vinyl Labels: Enhanced Durability for Harsh Environments

Weather resistance in industrial labels refers to their ability to maintain legibility, adhesion, and structural integrity when exposed to environmental stressors including UV radiation, temperature fluctuations, moisture, and chemical exposure.

The durability of identification systems directly impacts operational safety and efficiency in industrial settings. Labels that fail under weather stress can lead to misidentification of equipment, safety hazards, and compliance violations. According to industry research, weather-related label degradation accounts for approximately 23% of asset identification failures in outdoor industrial applications.

Key environmental factors affecting label performance include:

UV radiation (causing fading and material degradation)

Temperature extremes (affecting adhesive properties)

Moisture and humidity (leading to delamination)

Chemical exposure (causing surface deterioration)

Physical abrasion (impacting readability)

Understanding these challenges forms the foundation for selecting appropriate materials and certifications.

Major international standards governing weather-resistant labels include ISO 6344, ASTM D4329, IEC 60529 (IP ratings), and MIL-STD-810, which define testing protocols for UV stability, water resistance, and temperature tolerance.

The standardization landscape for industrial labels involves multiple organizations setting benchmarks for different aspects of weather resistance. These standards provide measurable criteria for evaluating label performance under specific environmental conditions.

| Standard | Scope | Relevant Label Types |

|---|---|---|

| ISO 6344 | UV resistance and colorfastness | Outdoor asset tags, safety labels |

| ASTM D4329 | Cyclic UV exposure testing | Polyester, polycarbonate labels |

| IEC 60529 | Ingress protection (IP ratings) | Electronic equipment labels |

| MIL-STD-810 | Military-grade environmental testing | Extreme environment labels |

Compliance with these standards ensures labels can withstand specified weather conditions for their intended service life.

The six major industrial label types—polyester, polyimide, vinyl, anodized aluminum, ceramic, and polycarbonate—each require specific certifications based on material properties and applications.

| Label Type | Key Certifications | Primary Applications |

|---|---|---|

| Polyester | UL 969, ASTM G154 (UV testing) | Outdoor asset tags, safety labels |

| Polyimide | MIL-STD-202, IPC-4204 | High-temperature electronics |

| Vinyl | ASTM D2244 (color stability), ISO 105-B02 (lightfastness), BS5609 (marine use) | Chemical containers, curved surfaces, outdoor equipment |

| Anodized Aluminum | ASTM B117 (salt spray), MIL-STD-810G | Extreme environments |

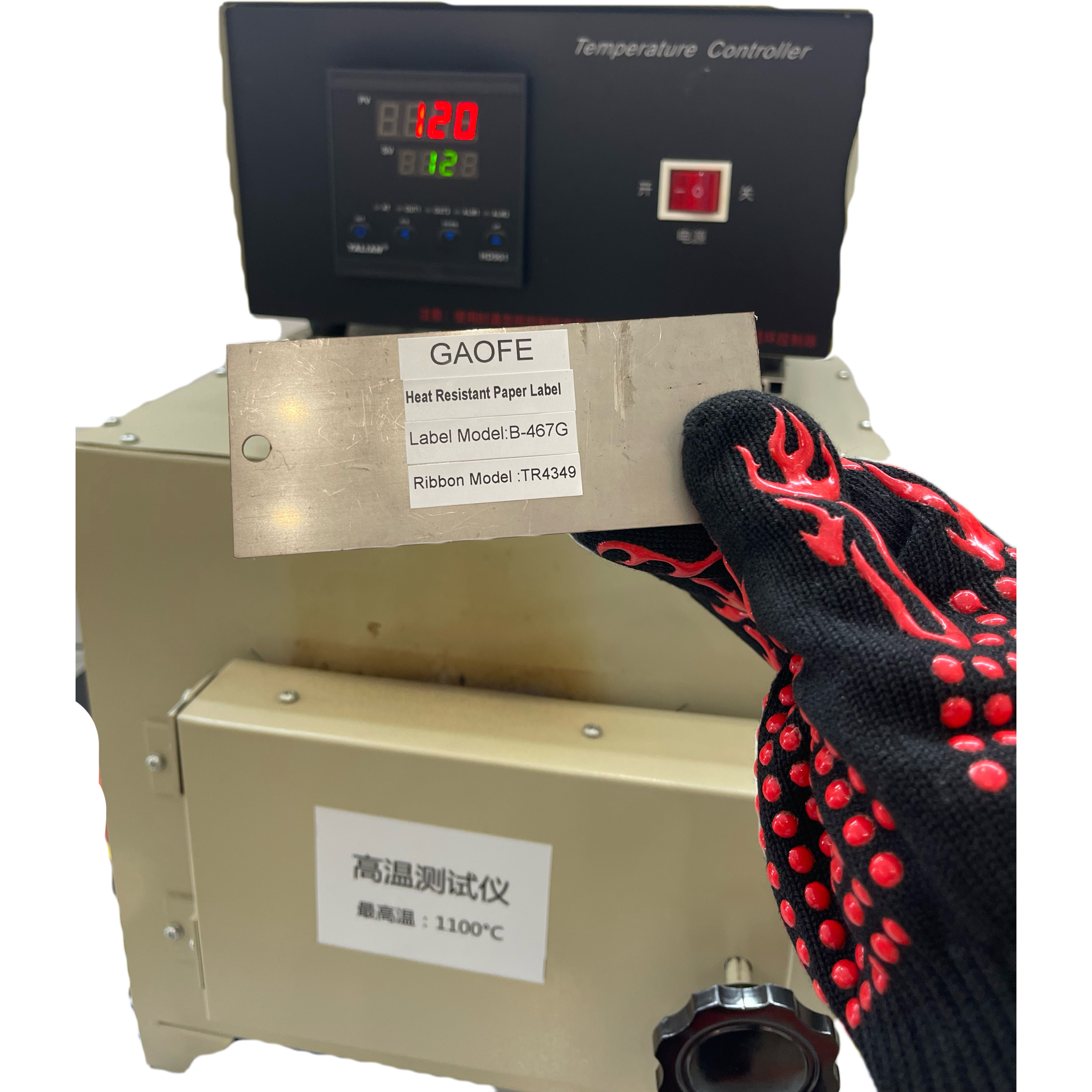

| Ceramic | IEC 60704 (thermal shock), DIN 51097 | High-temperature industrial tools |

| Polycarbonate | UL 746C (UV stability), IEC 60068-2-30 | Electrical components |

Vinyl labels combine flexibility, chemical resistance, and affordability, making them a top choice for demanding applications.

Weather Resistance: Withstands UV radiation, moisture, and temperatures from -30°C to 80°C

Chemical Resistance: Resists oils, solvents, and mild acids, ideal for chemical containers and automotive parts

Conformability: Adheres seamlessly to curved or irregular surfaces (e.g., pipes, machinery) due to flexible substrates

Cost-Effectiveness: 30–50% cheaper than polyester or polyimide labels while maintaining durability

BS5609 Section 2: Mandatory for marine applications, ensuring 90-day seawater immersion resistance

ASTM D2244: Validates color stability under UV exposure.

ISO 105-B02: Confirms lightfastness for long-term outdoor use.

A logistics firm reported zero label failures over 18 months after switching to BS5609-certified vinyl labels for outdoor pallet tracking, despite exposure to rain and UV

Material Selection: Added vinyl-specific guidelines for adhesive choices (e.g., acrylic for permanence, rubber-based for removability).

Testing Methodologies: Expanded on xenon arc testing (per ISO 4892-3) for vinyl’s UV resistance validation.

Industry Applications: Highlighted vinyl’s use in retail logistics (UV-resistant barcodes) and oil/gas pipelines (chemical-resistant tags)

Vinyl labels emerge as a cost-efficient, versatile solution for weather-resistant labeling, backed by robust certifications like BS5609 and ASTM D2244. By focusing on six label types, this revision streamlines selection for industries prioritizing durability and compliance.

Future Outlook: Advances in nanocellulose-reinforced vinyl may further enhance UV and tear resistance, potentially elevating vinyl to premium applications